Classification of express bags

Express bags are classified into express plastic bags, express document seals, express bubble bags, express bone bags, express woven bags, etc.

1. Courier bag material: low-density polyethylene (LDPE) is usually referred to as PE, and high-density polyethylene (HDPE) is usually referred to as PO. The courier bag has the advantages of low cost and light weight.

The difference between PE and PO in express plastic bags: PE has better transparency and softness, and the printing color is brighter; pO has relatively good mechanical properties; PE is used as the main material in domestic express bags, while foreign countries generally use PE. PE and PO composites are used as the main materials of express bags.

2. Courier document seal material: generally white cardboard with gray background, white cardboard, kraft cardboard, etc. The express industry generally uses paper with a weight of 200 g/m2 to 450 g/m2. Compared with express plastic bags, express document seals have the advantages of being flat and not easily broken.

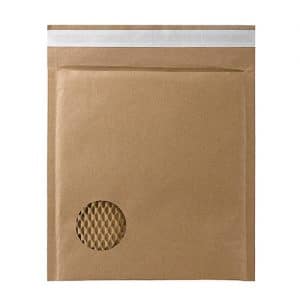

3. Material of express bubble bag: a transparent flexible packaging bag filled with air in the middle layer of the air cushion film. It is mainly used for the packaging of small volume fragile, easily damaged, and less precise goods in the express delivery industry. The express bubble bag is equipped with a shock-absorbing bubble film. There are countless small bubbles in the bubble film, so it is light and elastic, and has the advantages of good shock absorption, impact resistance, non-toxic, odorless, moisture-proof and corrosion-resistant.

4. Material of express bone bag: bone bag (also known as dense bag, free bag, sealed bag, zipper bag, self-sealing bag, polyethylene (LDPE) and high-pressure linear polyethylene (LLDPE) through blown film molding, eagerly cut Mechanism bag, a kind of plastic bag that can be released. Bone bags can be used for the inner and outer packaging of various small items. The self-sealing bag produced with food-grade raw materials can store various small food, tea, seafood, etc., moisture-proof, waterproof, insect-proof, prevent things from being scattered.

5. Express woven bags: also known as snakeskin bags. It is a kind of plastic, used for packaging, and its raw materials are generally polyethylene, polypropylene and other chemical plastic raw materials. The color of woven bags is generally white or off-white, non-toxic and tasteless, and generally less harmful to the human body. Although it is made of various chemical plastics, it is environmentally friendly and has strong recycling efforts; it is mainly used in various areas. It is used for packaging and packaging of articles, and has a wide range of industrial uses.

The above YBJ introduces the relevant content about the classification of express bags. Now, have you noticed that there are so many types of express bags, and different express bags are used in different fields?